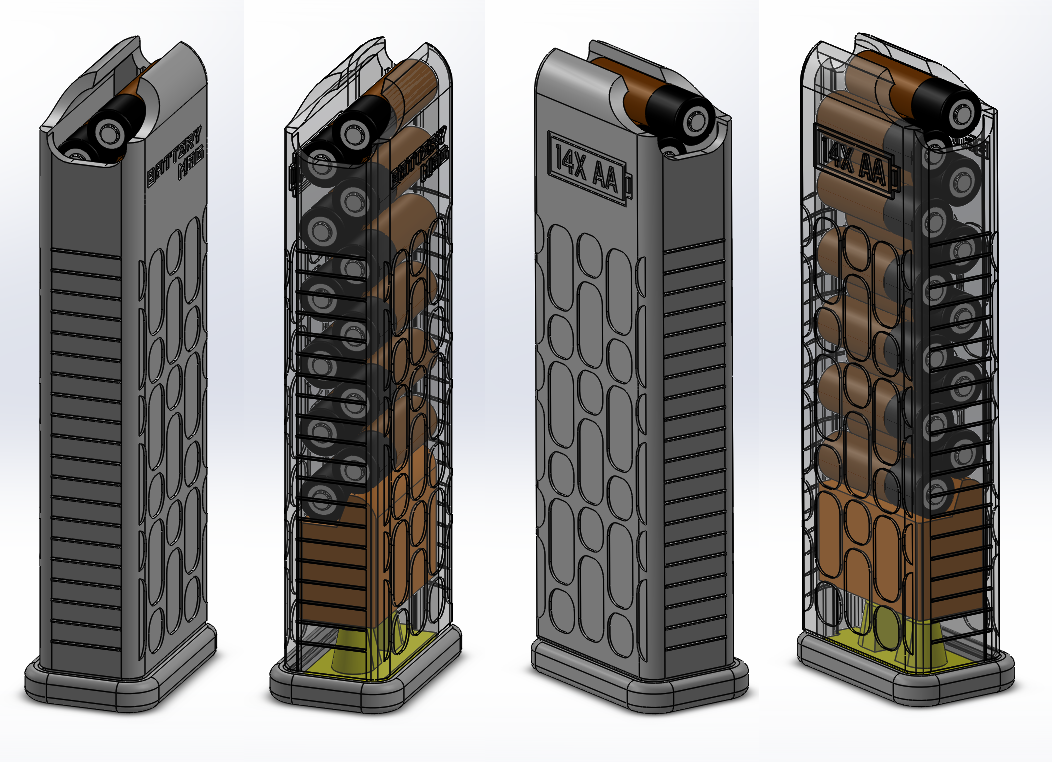

Using the newest engineering design software, we can help design your product and produce professional 3D CAD models and 2D engineering drawings, also knows as "prints".

Our experience spans thousands of parts, and hundreds of projects. We can create sophisticated designs, which take into consideration the user experience, Design For Manufacturing (DFM), Design For Assembly (DFA), material costs, part count, and many other factors. This produces higher quality parts, that require fewer design revisions, and get to market cheaper and faster.

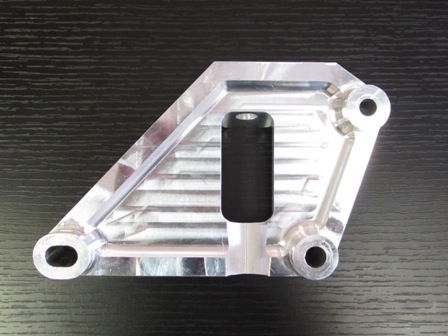

3D CAD models represent the ideal, nominal state of your design. Many modern manufacturing methods, often referred to as "digital manufacturing" or Model Based Design (MBD), can use CAD models directly to begin the process of producing physical parts. A great example of this is 3D printing, also called Additive Manufacturing (AM).

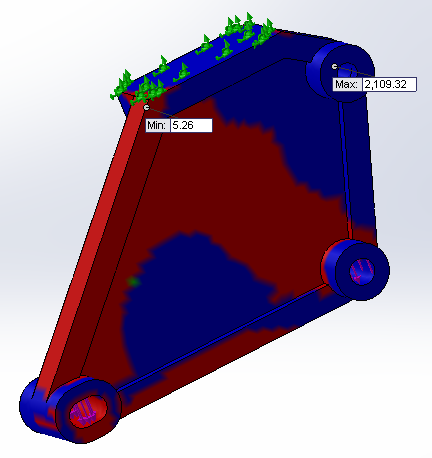

Sophisticated simulation software can also be used to predict the behavior of a part under different conditions, including stress loads, heat dissipation, shock, and vibration. Performing these analyses allows faster design iterations, saves costs by reducing the number of physical prototypes that must be made, and allows designs to be refined based on the results (e.g. removing unnecessary material from areas that receive little stress). to achieve desired results.

Engineering prints communicate your design intent, and provide a manufacturer with a crystal-clear contract specification to produce to. Even when CAD models can be used for direct manufacturing, prints are critical for providing specifications that must be met in production, such as the brand or quality of materials to be used, testing that must be done, and assembly processes that must be followed. Based on customer needs, we can provide engineering prints in a variety of detail levels, all the way up to full aerospace prints utilizing Geometric Dimensioning & Tolerancing (GD&T), fastener torque tables, and citing relevant industry and military specifications.